OUR PRODUCTS

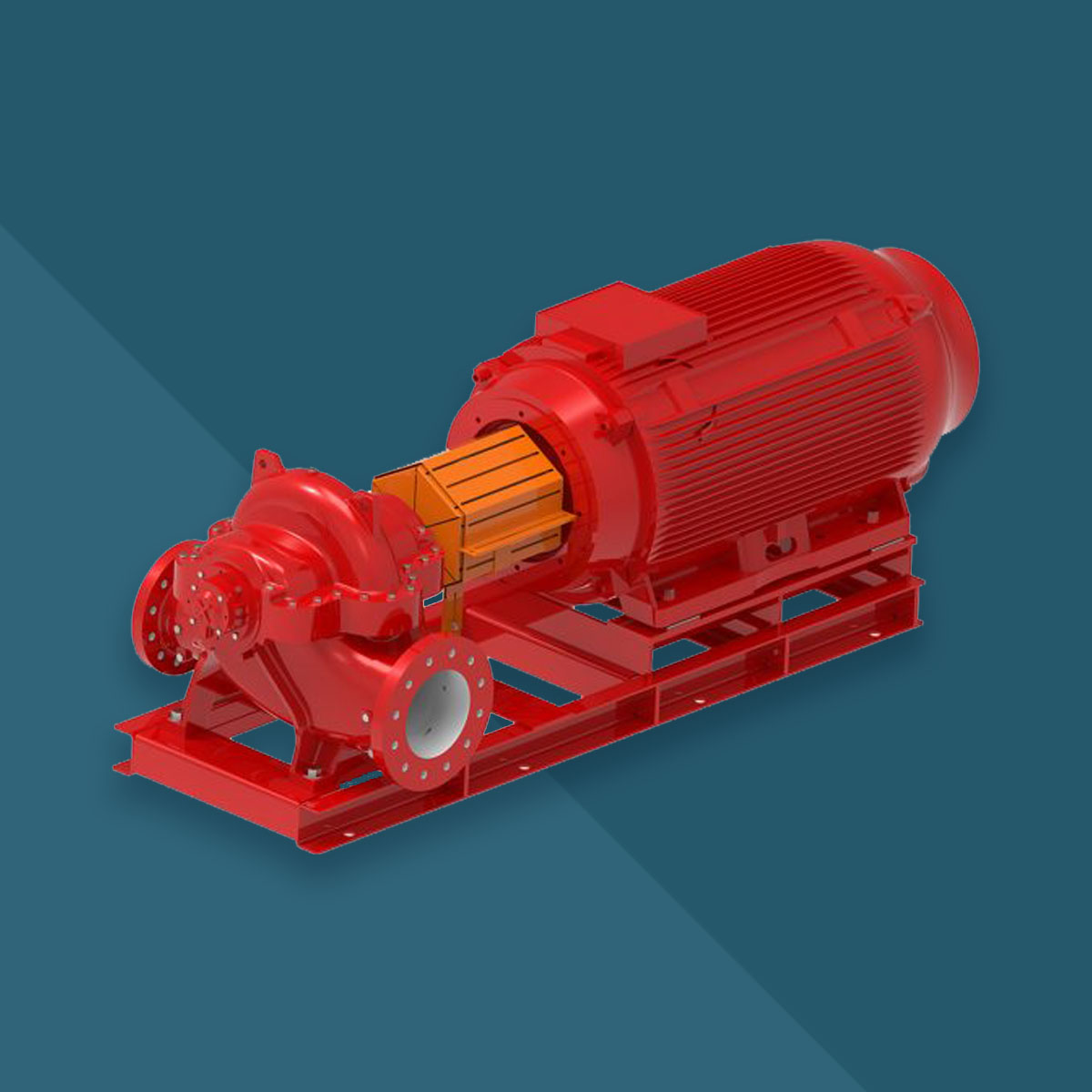

Industrial Pumps

Our high-quality industrial pumps systems are assured to provide reliable service to any HVAC or plumbing project. Applications for centrifugal pumps include hydronic heating and cooling systems, refrigeration, industrial, cooling towers, and irrigation.

Industrial Cooling Pumps for HVAC & Plumbing

We represent manufacturers that focus on efficient, reliable products that are easy to maintain. For hydronic systems, we carry a complete range of in-line and base-mounted centrifugal pumps.

For plumbing applications, we represent a number of manufacturers with specialized pumps for sump, sewage, wastewater, effluent, grinder, and more.

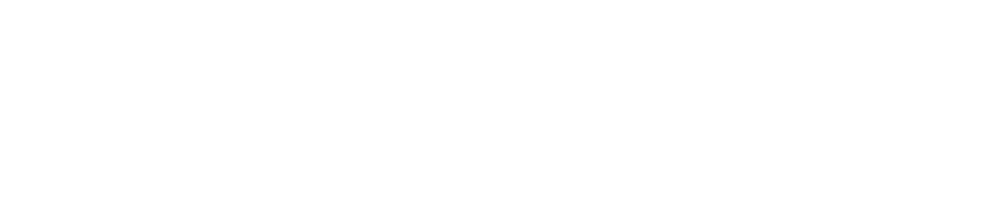

Centrifugal Pumps

Although every building is unique in architecture and operation, they all rely on an HVAC system to ensure the comfort, well-being, and productivity of their occupants. And although there are different designs and approaches to achieving proper indoor environmental control, double suction centrifugal pumps play a critical role in the performance of chillers, boilers, cooling towers, and hydronic distribution systems.

Sewage Pumps

Based on technology developed and tested in tough environments throughout the world, our sewage pumps feature a patented self-cleaning, which reduces clogging and maintains efficiency when pumping modern wastewater. Available in numerous sizes for flexibility and compatibility with a variety of installations.

Sump Pumps

Sump pumps are specifically designed for basement draining, dewatering, and water transfer. They have a range of capacities up to 70 GPM and maximum heads of 37 TDH ranging from 1/4 HP to 3/4 HP. The stainless steel or cast iron construction is available with 1-1/2” discharge connections. Battery back-up sump pumps are also available for emergency back-up service in the event of a power outage.

Hydronics Pumps

Designed and manufactured by the global leader in hydronic specialties technology, our double suction pump provides engineers, contractors, and building owners a more powerful, serviceable, and efficient solution for a wide range of critical HVAC applications.

Industrial Pump Brands and Products

Inline, close-coupled, base mounted, double suction, split case, and vertical turbine pumps for HVAC and plumbing

Condensate, boiler feed systems, and steam specialties

Stainless steel end suction, vertical multi-stage, self-priming, sump, effluent & sewage pumps

Chemical feed pumps, glycol feed systems & bypass feeders

Submersible, Column, Dry Pit, Grinder, and Sump & Sewage