We Distribute Hydronic Systems in Texas

Oslin Nation Co. is proud to be a hydronic systems componentry distributor — including plumbing products, valves, and tanks — throughout the areas of Austin, Dallas-Fort Worth, Houston, and San Antonio, Texas.

We want to be your systems experts and provide all of the components to complete your project.

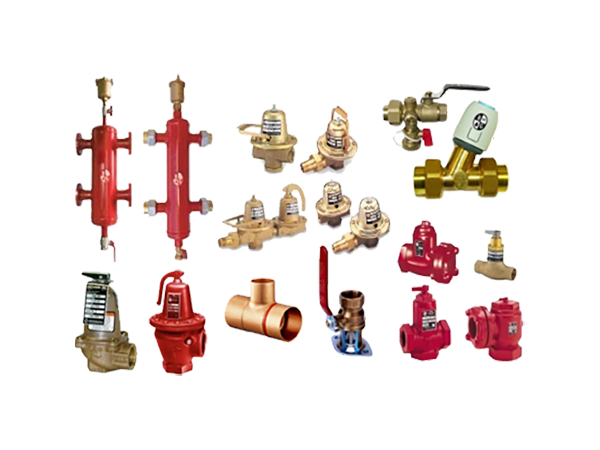

Hydronic Specialties

Discover unparalleled performance and reliability with our range of hydronic specialties, meticulously designed to optimize fluid-based heating systems. Engineered with precision and crafted from high-quality materials, our hydronic specialties seamlessly integrate into your heating infrastructure, ensuring efficient heat transfer and temperature control. From precision-engineered control valves to state-of-the-art expansion tanks, each product in our lineup is a testament to cutting-edge technology and innovation. Whether you’re looking to enhance energy efficiency, reduce operational costs, or simply elevate the performance of your hydronic system, our specialties deliver unmatched functionality and durability. Elevate your heating experience with our hydronic heating system components. Rely on our hydronic specialists — where excellence meets reliability.

Hydronic System FAQs

Hydronic heating systems utilize water as a medium to transfer heat, providing efficient and comfortable heating for various applications. The term “hydronic” refers to the use of water as the heat transfer fluid in these systems. In hydronic heating, hot water is circulated through pipes or tubing installed in floors, walls, or radiators, transferring heat to the surrounding space. This method is known for its even and consistent distribution of warmth, making it a popular choice for residential, commercial, and industrial heating. In a hydronic cooling system, it’s the opposite: Water is used for cooling purposes.

The two main types of hydronic heating systems are radiant heating and baseboard heating. Radiant heating systems involve the installation of tubing or heating cables beneath floors or within walls, emitting heat directly to the surfaces in a room. Baseboard heating, on the other hand, utilizes hot water-filled baseboard units or radiators to release heat into the air, which then rises to warm the room. Both systems offer energy-efficient and comfortable heating solutions tailored to different architectural preferences and requirements.

Hydronics refers to the study, design, and implementation of systems that use water as a heat transfer medium. This term is commonly associated with heating systems that utilize hot water to distribute warmth within a space. In hydronic systems, water is heated and then circulated through pipes, radiators, or tubing installed beneath floors or within walls. The heated water releases thermal energy, providing a comfortable and even distribution of warmth. Hydronics is known for its efficiency and versatility, making it a popular choice in various applications, including residential, commercial, and industrial heating.

In the context of HVAC (Heating, Ventilation, and Air Conditioning), hydronics specifically refers to the use of water-based systems for heating or cooling purposes. Hydronic HVAC systems typically include components such as boilers, pumps, and pipes to circulate hot or chilled water throughout a building. These systems are valued for their energy efficiency, precise temperature control, and ability to integrate with other HVAC components. Hydronics in HVAC plays a crucial role in achieving optimal thermal comfort while offering flexibility in design and application, making it a preferred solution in many heating and cooling scenarios.

Expansion Tanks

Experience optimal performance and longevity in your hydronic heating system with our premium expansion tanks. Specially engineered to accommodate the dynamic nature of fluid-based heating systems, our expansion tanks play a crucial role in maintaining system integrity. Crafted with high-quality materials and advanced manufacturing techniques, these tanks effectively absorb thermal expansion, preventing excessive pressure buildup and ensuring the system operates seamlessly. Our expansion tanks offer a reliable solution for controlling water volume fluctuations, contributing to increased efficiency and reduced stress on system components. Trust in the durability and precision of our expansion tanks to safeguard your hydronic system, providing peace of mind and enhancing overall performance. Choose excellence, choose reliability — choose our expansion tanks for a superior heating experience.

Expansion Tank Repair FAQs

The ability to repair an expansion tank is generally limited, as these devices are often sealed units designed to handle pressurized systems. When an expansion tank, particularly one associated with a home’s heating system or water lines, fails, it is typically due to a breach in the internal bladder or a failure in the tank’s integrity. Repairing such damage is not usually feasible because the internal components are not accessible for repairs, and attempting to seal leaks externally compromises the tank’s safety and effectiveness. Therefore, replacement is often the only viable solution once an expansion tank is compromised.

The cost to replace an expansion tank can vary widely based on several factors, including the type of tank, its capacity, the complexity of the installation, and regional labor rates. On average, homeowners might expect the cost to be somewhere between $200 to $400, including parts and labor. High-capacity tanks for larger systems or those requiring specialized installation procedures can drive the cost higher. It’s advisable to obtain multiple quotes from reputable service providers to ensure competitive pricing for the replacement.

Addressing a leak in an expansion tank directly is not a straightforward repair task for the reasons mentioned earlier. If the leak results from a faulty valve or connection, tightening or replacing these components might temporarily resolve the issue. However, if the leak originates from within the tank itself, such as through a breach in the internal bladder, the most appropriate and often the only solution is to replace the tank. It’s critical to address leaks promptly, as they can lead to system inefficiency, potential damage to other parts of the system, or even water damage to the surrounding area.

The life expectancy of an expansion tank can vary, but most are designed to last between 5 to 10 years under normal operating conditions. Several factors can affect this lifespan, including the quality of the tank, the conditions of its use, the presence of any corrosive chemicals in the water, and how well the system is maintained. Regular maintenance, including checking the pressure levels and ensuring the pre-charge pressure is correct, can help extend the life of an expansion tank. Additionally, installing the tank in a location that minimizes exposure to extreme temperatures and mechanical damage can also contribute to achieving or exceeding the expected lifespan.

Hydronic Valves

Hydronic valves play a pivotal role in the operation of hydronic heating and cooling systems, which use water as the medium to transfer heat or coolness throughout a building. These valves are integral components that control the flow of water or steam in the system, ensuring optimal temperature regulation and energy efficiency. There are several types of hydronic valves, including ball valves, gate valves, and balancing valves, each serving specific functions from shutting off flow entirely to precisely controlling the flow rate. Thermostatic radiator valves (TRVs) are another type, allowing for automatic adjustment of water flow to radiators based on the room temperature. The proper selection, installation, and maintenance of hydronic valves are critical for the system’s efficiency, reliability, and longevity. By effectively managing water flow, these valves contribute significantly to the comfort levels within residential or commercial buildings and play a crucial role in achieving energy conservation goals.