The Series e-1510, of the many Bell and Gossett pumps, has the biggest Efficiency Island compared to other pumps, and it also has the highest efficiency overall in the end-suction market for HVAC and plumbing applications. The Efficiency Island on the Series e-1510 centrifugal pumps lowers lifecycle costs and improves overall system performance.

The Series e-1510 centrifugal pumps has much higher efficiency levels over a larger range of operating conditions, and this improvement is thanks to the technological design of computational fluid dynamics (CFD). You can get these centrifugal pumps in 26 different sizes and various options for configuration that allow for flexibility and customization.

Applications

- Chilled Water

- Used as an efficient way to transfer thermal energy, which leverages the properties of chilled water to effectively cool and regulate temperatures for various applications.

- Cooling Towers

- Cooling towers are used in the Series e-1510 centrifugal pumps for industrial applications. These towers get rid of excess heat from industrial processes, ensuring longevity of equipment and optimal performance while conserving energy and promoting sustainability.

- Commercial HVAC

- These centrifugal pumps integrate commercial HVAC functionality to deliver comprehensive climate control solutions. The Series e-1510 circulates both chilled and hot water, which plays a crucial role in maintaining precise temperature conditions.

- Hydronic Heating and Cooling Systems

- Hydronic heating and cooling systems are used to help regulate temperatures, again utilizing water as a heat transfer medium, which ensures precise control over the pump’s heating and cooling process.

Series e-1510 Centrifugal Pumps Features

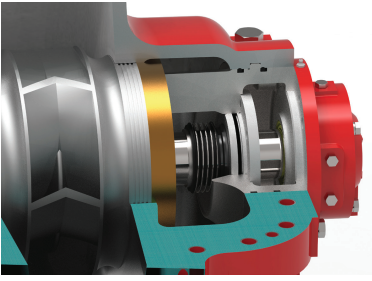

Center Drop-Out Spacer Coupling

The center drop-out spacer coupling allows for the bearing frame and rotating element to be removed without disturbing anything.

Heavy-Duty Baseplate

The baseplate is the standard for this pump, which provides a heavy-duty saddle assembly, closed baseplate ends, and an open top to provide ease of access for the grouting of proper equipment.

True Back Pullout

Assures ease of service, and doesn’t disturb the motor and piping. Eliminates a need for repairing delays.

OSHA-Compliant Coupling Guard

This centrifugal pump’s coupler guard complies with OSHA 1910.219, and offers increased protection against any potential injuries, and is standard for the Series e-1510 centrifugal pumps.

Stainless Steel Impellers & Internally Self-Flushing Mechanical Seal

The impellers on the Series e-1510 centrifugal pumps are robust, providing excellence in durability and corrosion resistance. These impellers are built for longevity and a reliable performance. The mechanical seal is also designed with longevity in mind, and the configuration ensures efficient flushing of contaminants, maintaining optimal centrifugal pumps performance over a long period of time.

Centrifugal Pump Options

- Stainless Steel Volute Wear Ring

- The stainless steel volute wear ring enhances the system’s reliability by reducing friction and maintaining efficient fluid flow, which contributes to consistent performance and prolonged pump life.

- Rexnord Omega Spacer Coupling

- Engineered with precision in mind, the Rexnord Omega Spacer Coupling minimizes vibration and ensures reliable power transmissions.

- External Flush Line

- This feature allows for easy flushing of the system, contributing to extended pump life and sustained reliability in diverse industrial and commercial applications.

- Epoxy Coated Internal Cast Iron Components

- This protective coating ensures the longevity of critical pump elements, as well as the system’s reliability and suitability for a wide range of applications in industrial and commercial settings.

| Standard Mechanical Seal | SM, LG, and XL Bearing Frames | ES Bearing Frame |

| Hardware | Stainless Steel / Brass | Stainless Steel |

| pH Limitations | 7.0 – 9.0 | 7.0 – 9.0 |

| Elastomer | Buna | Buna |

| Stationary Face | Ceramic | Silicon Carbide |

| Stationary Face | Ceramic | Silicon Carbide |

| Temperature Range | -20 to 225°F | -20 to 225°F |

| Maximum Pressure | 175 PSI | 175 PSI |

| Mechanical Seal Options | SM, LG, & XL Bearing Frames | ||

| Rotating Face | Carbon | Carbon | Silicon Carbide |

| Hardware | Stainless Steel / Brass | Stainless Steel | Stainless Steel |

| Stationary Face | Tungsten Carbide | Ceramic | Silicon Carbide |

| Elastomer | EPR (Ethylene Propylene Rubber) | FKM (VitonTM or

Fluoroelastomer) |

EPR (Ethylene Propylene Rubber) |

| Temperature Range | -20 to 250°F | -10 to 225°F | -20 to 250°F |

| pH Limitations | 7.0 – 11.0 | 7.0 – 9.0 | 7.0 – 12.5 |

| Maximum Pressure | 175 PSI | 175 PSI | 175 PSI |

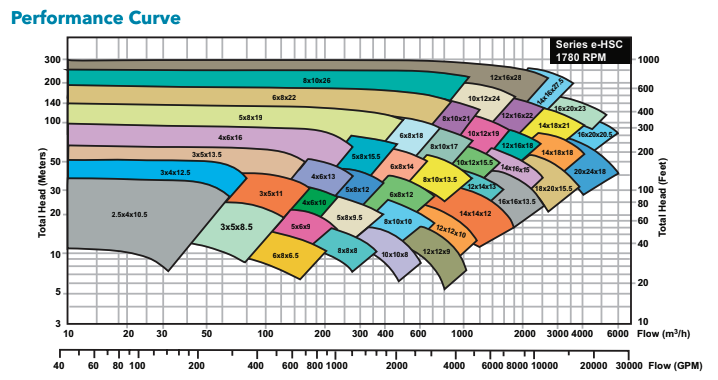

Oslin Nation Are Bell and Gossett Distributors

We are the Bell and Gossett distributor in Houston, Austin, San Antonio, and Dallas, Texas. For more information on Bell and Gossett’s new Series e-HSC Double Suction Centrifugal Pumps, contact us.