What is an Expansion Tank?

An expansion tank is a small tank used to protect closed water heating systems and domestic hot water systems from excessive pressure. It is designed to absorb the extra volume of water created when the water is heated and expands.

How Does an Expansion Tank Work?

When water is heated, it expands and creates additional pressure within the system. Without an expansion tank, this pressure can cause pipes to burst, valves to fail, and pumps to malfunction. The expansion tank provides a space for the extra water to go, preventing these issues. Wessels manufactures expansion tank products that are built in accordance with the ASME code.

Types of Expansion Tanks

Wessels manufactures three expansion tank designs: Compression, Bladder and Diaphragm. Each tank style has models that are either built in accordance with the ASME boiler and pressure vessel code or non-code. Tanks range in size from 2 to 10,000 gallons. Most of Wessels pressure vessels are designed using a pre-pressurized vessel with an internal bladder or diaphragm to manage fluids under pressure. The majority of Wessels products are standard catalog models, with over 6,000 tanks in inventory for quick shipment.

Compression Expansion Tanks

Compression tanks are designed to absorb expansion forces and control the pressure in heating/cooling systems. This tank is the oldest style design and works well when the air is controlled and kept in the tank, not in the system.

Stainless Steel NA Series

SSNA Series Stainless Steel vessels:

- Fabricated from 304 stainless steel

- Sizes range from 15 to 400 gallons

- 316L stainless steel available

NAG Compression Tanks (ASME)

The NAG Series Compression tanks are ASME plain carbon steel expansion tanks. They are designed to absorb the expansion forces and control the pressure in heating / cooling systems. Wessels manufactures compression tank products built in accordance with the ASME code.

Diaphragm Expansion Tanks

Diaphragm expansion tanks feature a rubber diaphragm that separates the water from the air inside the tank. As water heats and expands, it pushes against the diaphragm, compressing the air on the other side. This design helps maintain consistent pressure and prevents water from mixing with the air, which can cause corrosion.

The diaphragm tank has been developed to allow the systems air cushion to be separated from the system’s water. No waterlogging of the tank can occur as the air is held between the tank wall and the outside of a bladder placed inside the tank, while the system water is contained inside the bladder. This changes the system to an air elimination system, as any air extracted from the system water is passed out of the system into the atmosphere.

The diaphragm cannot be replaced if the tank fails. The advantage of this style is the initial cost. On smaller tanks the cost of replacing the bladder may exceed the cost of replacing the tank. Wessels manufactures diaphragm tank products built in accordance with the ASME code.

The NTA Series:

- Built in accordance with the ASME boiler and pressure vessel code

- Heavy-duty fixed butyl diaphragm

- Sizes range from 8 to 211 gallons

N Expansion Tanks (Non-ASME)

The N Series:

- Heavy-duty fixed butyl diaphragm

- Sizes range from 2 to 80 gallons

Bladder Expansion Tanks

Bladder expansion tanks use a bladder made of rubber or synthetic material to separate the water and air. The bladder expands and contracts with changes in water volume, maintaining pressure balance within the system. This type of tank is often used in larger systems due to its durability and efficiency.

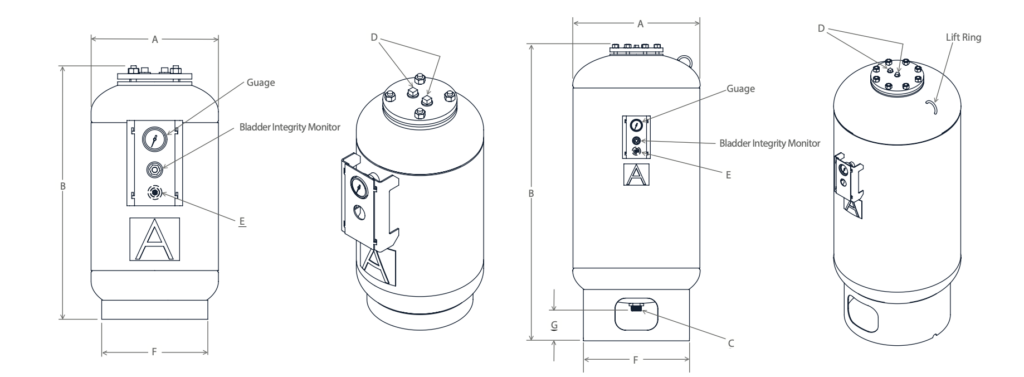

Wessels type NLA removable bladder expansion tanks are designed for use in hydronic heating/cooling systems to absorb the expansion force resulting from the changes in temperature of the heating/cooling fluid. They’ve been intelligently designed to include a WessView® bladder integrity monitor and integrated air-side pressure gauge.

NLA Series (ASME)

The NLA is the industry’s broadest line of bladder style tanks with a range of smart tank features that include:

- Built in accordance with the ASME boiler and pressure vessel code

- WessView® Bladder Integrity Monitor

- Air-side pressure gauge

- Heavy-duty replaceable butyl bladder

- Sizes range from 10 to 4,000 gallons

- Working pressures of 125 PSI (std), 200 and 250 PSI

NVA Series (ASME)

- Built in accordance with the ASME boiler and pressure vessel code

- Bottom system connection design

- Heavy-duty replaceable butyl bladder

- Sizes range from 20 to 4,000 gallons

- Working pressures of 125 PSI (std), 200 and 250 PSI

NLAP Series (ASME)

NLAP Expansion Bladder Tanks:

- Built in accordance with the ASME boiler and pressure vessel code

- Top system connection design

- Heavy-duty replaceable butyl bladder

- Sizes range from 11 to 290 gallons

NL Series (Non-ASME)

NL Expansion Bladder Tanks:

- Heavy-duty replaceable butyl bladder

- Sizes range from 2 to 132 gallons

Benefits of Using an Expansion Tank

Preventing System Damage

Expansion tanks prevent damage to heating and cooling systems by absorbing excess pressure, protecting components like pipes, valves, and pumps from failure.

Enhancing System Efficiency

By maintaining consistent pressure, expansion tanks help systems operate more efficiently. This can lead to reduced energy consumption and lower utility bills.

Extending System Lifespan

With less pressure-induced stress on components, systems equipped with expansion tanks tend to have a longer lifespan. This reduces the need for frequent repairs or replacements, saving time and money in the long run.

Installation and Maintenance Tips

Proper installation and maintenance are crucial for the effective functioning of an expansion tank. Here are some tips:

- Installation: Always follow manufacturer guidelines for installation. Ensure the tank is properly sized for your system to handle the expected volume of expanded water.

- Maintenance: Regularly check the tank’s pressure and inspect for signs of wear or damage. Diaphragm and bladder tanks require less maintenance compared to plain steel tanks, which need periodic air cushion replenishment.

Expansion tanks play a vital role in protecting and maintaining heating and cooling systems. They absorb excess pressure, enhance efficiency, and extend the lifespan of system components.

For more information, visit Wessels Company. To understand broader applications and see more products, check out Hydronic Specialties and Tanks.