In the world of industrial HVAC systems and high-power inverter operations, the reliability and longevity of motor components are critical to ensuring seamless operations and minimizing downtime. A common issue encountered in these systems is the damage caused to motor bearings by harmful electrical currents. This is where CoolBLUE® Inductive Absorbers step in as a game-changer, significantly enhancing motor performance and extending the service life of your equipment.

Understanding the Problem: Motor Bearing Currents

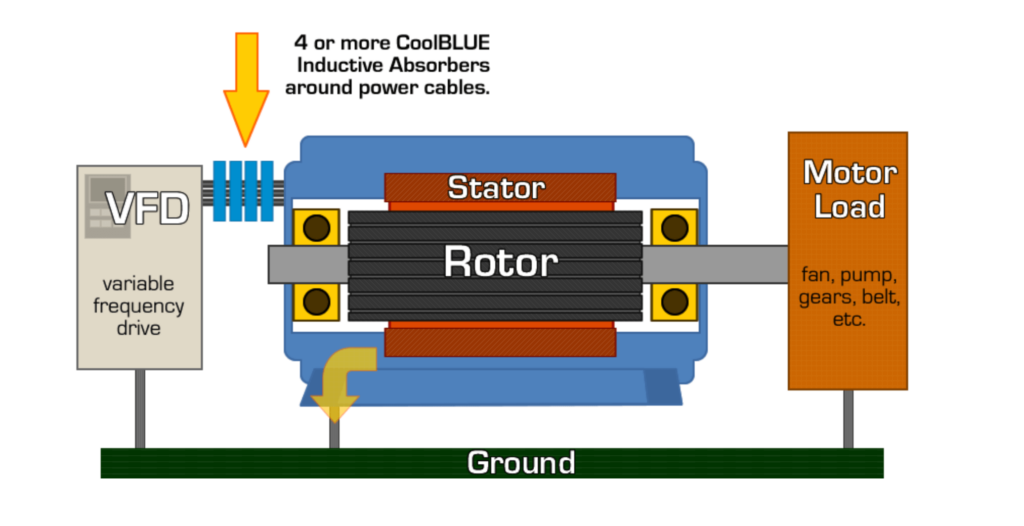

Electric motors, especially those connected to variable frequency drives (VFDs), often suffer from bearing damage due to unwanted currents. These destructive currents lead to wear and tear in motor bearings, causing operational failures and costly repairs. Traditional solutions, such as grounding rings, attempt to address this issue but come with their own set of drawbacks, including intricate installation requirements, the necessity for periodic replacements, and limited compatibility with various motor sizes.

The Solution: MH&W Nanotech CoolBLUE® Inductive Absorbers

CoolBLUE® Inductive Absorbers provide an innovative solution to the problem of bearing currents. Made from the nanocrystalline material Magnetec NANOPERM®, these absorbers function as common mode chokes, effectively suppressing EMI (electromagnetic interference) currents and preventing them from reaching the motor. The result is a significant reduction in voltage peaks and enhanced protection of motor bearings.

Key Benefits of MH&W Nanotech CoolBLUE® Inductive Absorbers

- Easy Installation: Unlike traditional grounding rings that require precise alignment and significant installation time, CoolBLUE® cores can be installed quickly and easily without extensive downtime. Their straightforward application allows them to be retrofitted into existing systems on-site, even in harsh conditions.

- Long-lasting Performance: CoolBLUE® Inductive Absorbers are designed to last the lifetime of your motor system. Unlike mechanical solutions that require frequent replacements and special parts for different motor sizes, these absorbers offer a ‘set-it-and-forget-it’ solution, needing only one choke per system.

- No Motor Modifications Required: The use of CoolBLUE® cores requires no modifications to your motor or shaft preparation. There is no need for insulated or hybrid bearings, making them compatible with all motor sizes without the hassle of additional parts even in applications with wash-down requirements.

- Enhanced Motor Protection: By absorbing common mode currents before they reach the motor, CoolBLUE® Inductive Absorbers prevent the currents from causing bearing damage or other detrimental effects, ultimately increasing motor longevity and reducing maintenance costs.

- Cost-Effective: Not only do they reduce maintenance and operational costs by extending the service life of motor bearings, but they also avoid the high installation costs and complexities associated with grounding rings. This results in a substantial overall saving in the long run.

Why Choose CoolBLUE®?

In comparison to traditional solutions, CoolBLUE® offers a more efficient, durable, and cost-effective way to protect your motor systems from bearing deterioration and unnecessary breakdowns. If you’re looking to enhance the reliability and extend the operational life of your industrial HVAC machinery, consider integrating CoolBLUE® Inductive Absorbers into your system. With less downtime and reduced maintenance expenses, these absorbers can be the right choice for maximizing your business’s productivity and efficiency.

By choosing CoolBLUE®, you’re investing in a smarter, more sustainable future for your industrial operations. Make the switch today and experience the difference in motor performance and longevity!

MH&W Nanotech (otherwise known as CoolBLUE®) Distributors

As authorized MH&W Nanotech distributors, we provide prompt access to MH&W Nanotech’s industry-leading solutions, meeting the diverse needs of clients in Austin, Houston, and San Antonio, Texas.