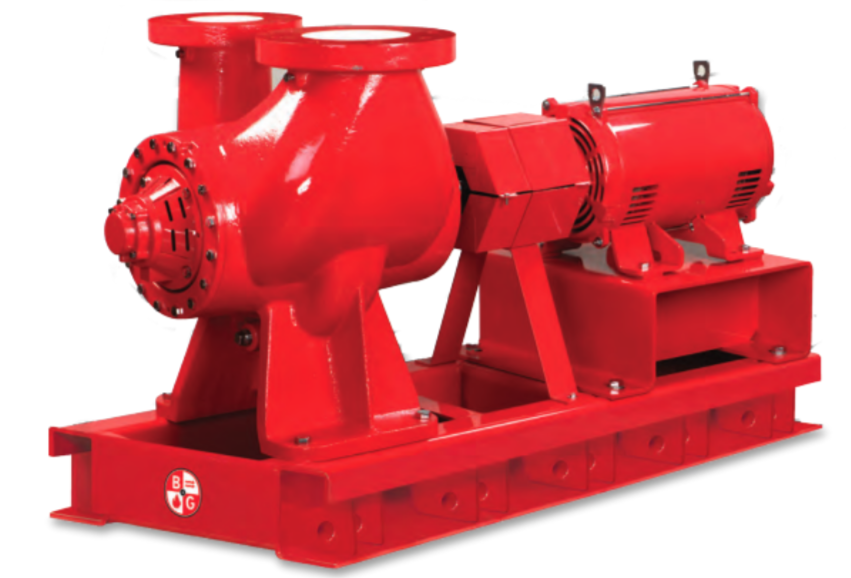

Bell and Gossett has over 100 years of experience with pumps, so not only do they know how to design them, but also, they know how they work. However, when it was time to give the double suction VSX pumps an update, they turned to their audience, the experts who use the pump.

What does the term double suction pump refer to?

Double suction industrial pumps, often used in applications requiring a high flow rate, refers to a type of centrifugal pump that is designed with a unique impeller structure allowing fluid to enter from both sides. This design significantly reduces the axial thrust and load on the pump’s bearings, leading to a more balanced operation and extended lifespan. In the context of VSX (Vertical Split-case eXtended) pumps, the double suction configuration is especially beneficial, as it can handle larger volumes of liquid efficiently, making these pumps ideal for water intake, cooling systems, and large-scale irrigation systems.

What is the difference between a single entry and a double entry impeller?

The primary difference between a single entry and a double entry impeller lies in how the fluid enters the impeller. In a single entry impeller, fluid enters the impeller from one side only. This can create an unbalanced hydraulic load on the impeller, leading to higher axial thrust and potentially increased wear on the pump’s bearings and other components. Conversely, a double entry impeller, as found in double suction pumps, allows fluid to enter from both sides. This design balances the hydraulic forces on the impeller, reducing axial thrust, improving efficiency, and potentially extending the pump’s operational life, especially in high-flow applications like those handled by VSX pumps.

One Pump That Does It All

The new design for the double suction VSX pump includes a new hydraulic design, with some of the following features:

- Working pressures of 175 and 300 pisg / 12 and 20 Bar

- Temperature 0 to 300ºF / -17 to 148ºC

- Heads from 30 to 530 feet / 9 to 161 meters

- Flows from 500 to 28,000 GPM / 114 to 6400m3/h

Features

There have been new and updated features to the VSX pumps, including:

Maintenance-Free Bearings

Now there’s no more need for regular bearings maintenance, over-greasing, or mixing greases! With maintenance-free bearings, your VSX pump will last longer than ever before.

Alignment-Friendly Coupling

Alignment protection for the VSX pump was designed to make the performance of the pump last, and the hubs won’t move during inspection thanks to the easy split element design.

What is the difference between end suction and split casing pump?

The difference between end suction and split casing pumps primarily lies in their construction and flow handling capabilities. End suction pumps have a simple design where the liquid enters from one end and is discharged from the top. On the other hand, split casing (or double suction) pumps are designed with a casing that is split horizontally or vertically, allowing easy access to the impeller and internals without disturbing the motor or piping. The VSX type double suction pumps’ split casing design offers superior performance for large volume and high-pressure applications.

Groutless Base Plate

The double suction VSX pumps have a new groutless base plate, which is state-of-the-art and makes for a faster installation.

How do I identify a Bell and Gossett pump?

As Bell and Gossett distributors, identifying a double suction pump typically involves looking for specific markers that distinguish it from other pumps. Firstly, check for the Bell and Gossett brand name or logo on the pump body, which is a clear indicator. Additionally, Bell and Gossett pumps often have a nameplate or identification plate attached, which provides crucial information such as the model number, serial number, and specifications like capacity, head, and power requirements. For their double suction VSX series pumps, specific model designations may be used to indicate the double suction feature, so reviewing technical documentation or the company’s product catalog can also aid in identification.

Bell and Gossett Distributors

As an authorized distributor, we ensure prompt access to Bell and Gossett’s industry-leading solutions, which meet the various demands of clients across the areas of Dallas, Houston, San Antonio, and Austin, Texas.