With the rising costs of fuel and other commodities, people across all sectors are looking for ways to cut costs, increase efficiency and ensure greater return on investment. Our team at Oslin Nation can suggest some ways to add longevity and efficiency to your system, both in the short and in the long-term. We take pride in the manufacturers we represent, both in their quality and their longevity. Lets go through a few ways to further increase efficiency.

Variable Frequency Drives

Variable Frequency Drives

Variable Frequency Drives or VFD’s primary function is to provide energy savings. By controlling speed of a pump rather than controlling flow through use of throttling valves, energy savings can be substantial. By way of example, a speed reduction of 20% can yield energy savings of 50%. Systems need to integrate VFD’s to regulate the motor speed and optimize efficiency. And, by adding sensors at key points in the system, the VFD’s can be more effective because they are provided real-time data. VFD’s also help to reduce wear and tear on the equipment because otherwise the pump would be running continuously.

Condensing Boilers

Condensing Boilers

Every system is different, and the requirements of the system dictate the type of equipment used, But, if the engineer has the option to utilize a higher-efficiency condensing boiler system as opposed to a non-condensing system, they can take advantage of increased production and reduced loss of energy due to the process of the system. Whenever possible converting to a condensing system will provide optimal energy costs throughout the year.

Low Temperature Valves

In situations where a non-condensing boiler system is necessary one way to operational life-span is to add a low-temperature valve in the hot water return line. The low temperature valve helps to protect the boiler, as its purpose is to ensure that the return water temperature to the boiler is not too cold which will cause condensation to form on the heat exchanger. Cold water return is one of the leading causes of premature heat exchanger failure for non-condensing appliances. Green and white residue on the heat exchanger is a sign condensing or short cycling is occurring.

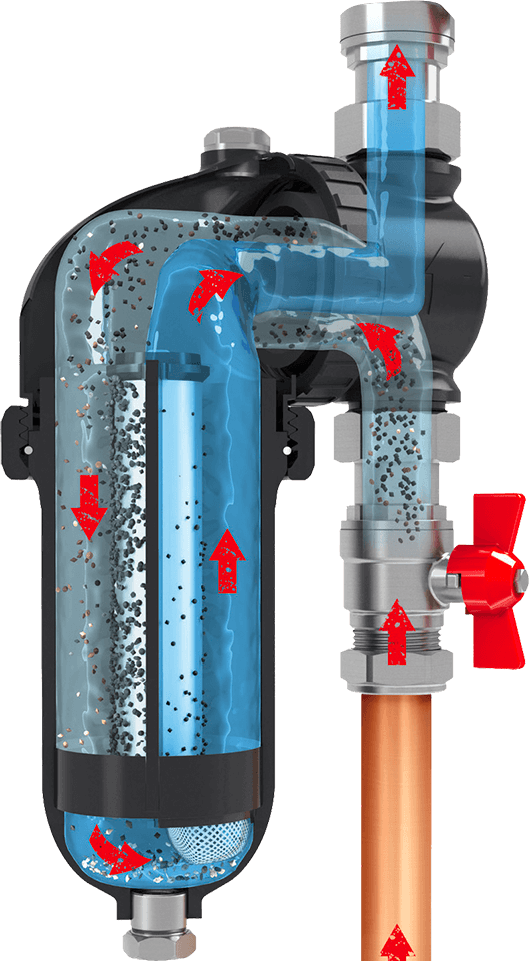

System Add-Ons

Other products like strainers, magnetic strainers, and magnetic filters can potentially help to add to the life of the system, increasing the time before replacement is necessary. These products are often an after-thought, but when used effectively can add peace of mind to the owner or user of the system.

Costs are increasing, but with a little smart planning and some added knowledge, greater efficiency and economy can be achieved. Give our experienced team a call and we will do everything we can to help you achieve the cost-effectiveness you are looking for. Give us a call – 1-877-ONCO-TX-0