In an evolving industrial landscape, where efficiency and adaptability are paramount, the Metraloop® expansion joint emerges as a dynamic piping component solution that surpasses the capabilities of traditional joints. Renowned for its versatility, the Metraloop® is engineered for thermal and seismic applications across a broad spectrum of piping systems, from hot water and steam to gas and fire sprinkler lines. This innovation ensures that, regardless of the direction or application, the Metraloop® can significantly enhance system resilience and performance.

What Sets the Metraloop® Apart

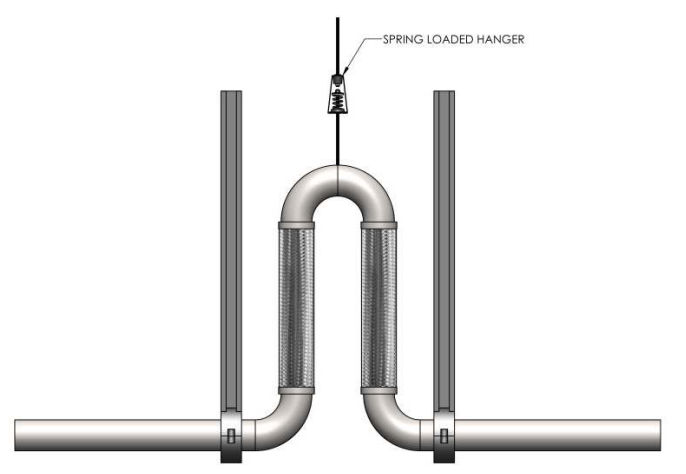

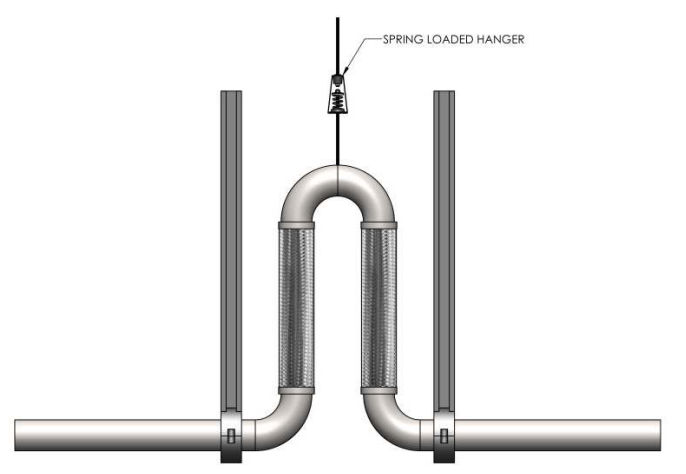

Unlike conventional expansion joints, the Metraloop® employs advanced hose and braid technology, allowing for multidirectional movement—axial, lateral, and angular—while also minimizing the need for extensive guides and anchors. By integrating this dynamic capability, the Metraloop® not only simplifies system design but also effectively reduces stress on pipelines, contributing to improved longevity and reduced maintenance costs.

Metraloop® Expansion Joint Features

- Time-tested Hose and Braid Technology: Provides superior flexibility and durability.

- Elimination of Thrust Loads: Results in lower anchor loads and minimal guiding requirements.

- Compact Installation: Easier and faster to install than traditional pipe loops, saving time and space.

- Multi-directional Movement: Accommodates axial, lateral, and angular movements.

- Variety of Sizes: Available in stock and custom configurations up to 84” diameter with movement designs exceeding 60”.

- Certification: Models are UL, FM, UPC, IAPMO, and CSA listed.

- Material Options: Choose from carbon steel, copper, or stainless steel ends with bronze or stainless steel flexible hoses.

Applications and Uses

The Metraloop® is ideal for a range of industrial applications, facilitating the transport of hot and chilled water, steam, potable water, and more. Its ability to absorb both thermal expansion and seismic movements makes it indispensable in environments prone to fluctuations, ensuring safety and operational continuity. By significantly reducing line stresses, the Metraloop® provides a streamlined approach to designing and maintaining efficient piping systems.

Options and Customizations

It offers a range of custom options to meet specific requirements, including liners for high-velocity materials, protective exterior coatings for corrosive settings, and double braiding for high-pressure or steam applications. These options ensure the Metraloop® can be tailored to the most demanding environments while maintaining optimal performance.

Installation and Maintenance

Installation of the Metraloop® is straightforward, with guidelines in place to ensure proper setup across varied applications. Designed to be maintenance-free, it requires no serviceable parts, with periodic visual inspections suggested, especially following seismic events. This ease of use further enhances its value as a smart investment for industrial operations.

Conclusion

In conclusion, the Metraloop® expansion joint stands as a testament to Metraflex’s commitment to innovation and engineering excellence. By addressing the challenges of thermal and seismic piping movements with precision and adaptability, the Metraloop® redefines efficiency and reliability in industrial settings. For those seeking advanced solutions to enhance their piping systems, the Metraloop® offers unmatched benefits and enduring value.

Proud Distributors of Metraflex Products

As authorized

Metraflex distributors, we provide prompt access to Metraloop®’s cutting-edge solutions, meeting the diverse needs of clients in Austin, Houston, and San Antonio, Texas, with efficiency and reliability.