The Bell & Gossett Series e-80 in-line mounted centrifugal pump is a highly efficient, heavy-duty, close-coupled pump that lowers operating and maintenance costs. Available in sizes 1.5” through 8”, it delivers a broad efficiency range for fixed or variable speed operation.

The Series e-80 pump integrates with an optional variable frequency drive, and has sensored or sensorless control capabilities, further increasing its potential for performance and efficiency. Designed for horizontal and vertical in-line mounting, it’s ideal for hydronic heating and cooling systems, light industrial processes and general service.

Product Features

- Best-in-class hydraulic performance

- Low operating and maintenance cost

- Optional flange mounting supports

- Horizontal or vertical installation

- Several seal options

- Integrated variable speed drive (optional)

- Sensored or sensorless control capability (optional)

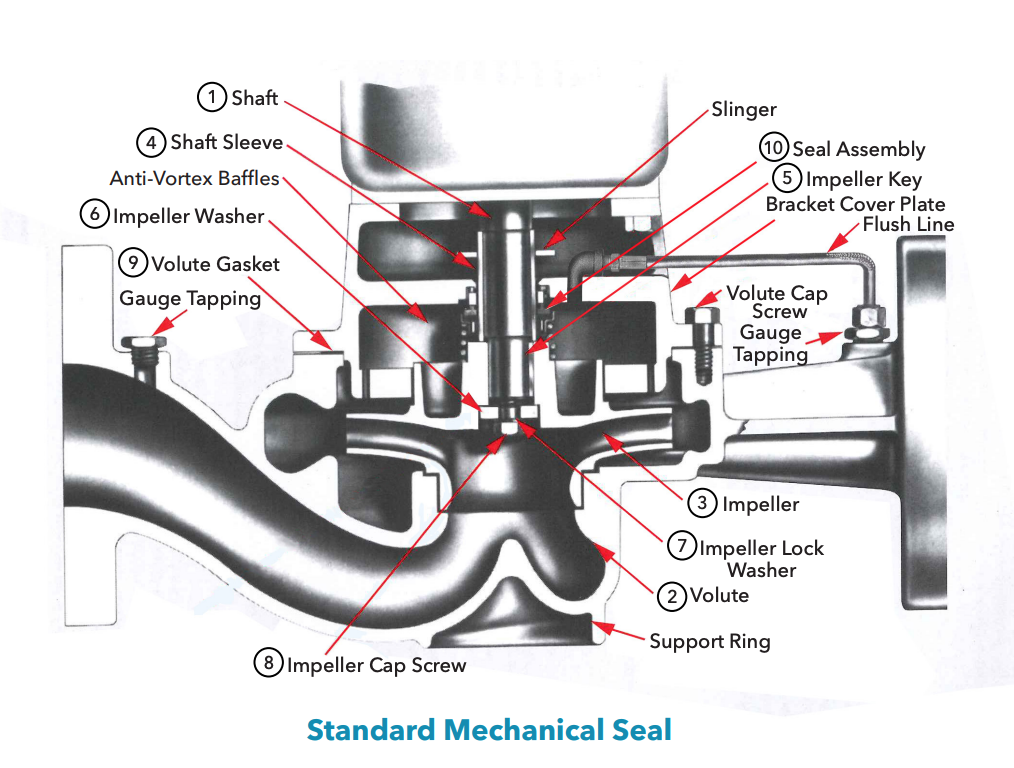

Mechanical Seal Design

The seal of the Series e-80 pump has a compact Rotating Unitized Seal Head design for easy seal replacement. The e-80 pump includes a standard internally flushed mechanical seal with a maximum working pressure of 175 psi. Two optional mechanical seals, each with a maximum pressure of 250 psi, are also available, one is installed internally and one for external installation. Both seal types utilize an external flush line to prolong seal life.

Shaft Jacking Coupling

The Series e-80 pumps feature a patented shaft jacking coupling design to simplify maintenance. This allows one serviceman to replace the mechanical seal without the need for an additional person to help lift the pump shaft during reassembly. This innovative feature is a major benefit for service contractors and building owners as it can reduce labor cost and pump downtime by 40% (depending on mechanical room layout and availability of lifting equipment).

Premium Efficient Motors

The Series e-80 pump features a standard NEMA Premium JM vertical solid shaft motor in a drip-proof enclosure when the standard mechanical seal is selected, and a NEMA Premium JP motor when a stuff box configuration is preferred. Premium efficient motors with TEFC enclosures are available options. Motors range from .75 to 50 hp at 1750 rpm, and 5 to 60 hp at 3500 rpm. A precisely machined cast iron motor bracket allows the motor to be rotated at 90° intervals to allow convenient positioning of the junction box.

Motor Bracket

Precisely machined rigid cast iron motor bracket ensures positive concentric alignment between motor and pump components. This helps promote maintenance free operation and contributes to pump longevity.

Easy Installation, Service and Maintenance

The bottom of the volute is tapped with four bolt holes to accept an ANSI/ASME flange, which provides temporary support while installing the pump. The back pull-out design allows the Series e-80 pump to be serviced without disturbing the piping, which means repairs can be made quickly and easily, and downtime is kept to a minimum. Flush-line filters and sediment separators are available on special request.

Integrated Variable Speed Drives

Provide variable flow pumping for the broadest range of applications with optional Bell & Gossett variable speed drives. The Integrated Technologic Sensorless Control drive (ITSC) combines the energy savings of variable flow with sensorless curve control to provide turn down at low flow while eliminating the cost and time of using wired transducers and sensors. The Integrated Technologic drive (IT) is another variable speed option designed for building automation system control. It provides an energy efficient and economical alternative for applications that don’t require sensorless control.

PPS Controller

Integrate up to eight Series e-80 pumps in parallel operation for sensored or sensorless control using an optional, Technologic sensorless or sensored controller. It features a large display screen that shows actual system performance via real-time graphical displays of the hydraulic pump curve, system curve and control curve. As pumps are added to the parallel pumping system, efficiency increases because each pump works less. Plus, individual pumps can be staged ON/OFF more effectively, thanks to the controller’s wide hydraulic efficiency range.

Applications

- Hydronic heating & cooling systems

- Light industrial process

- General service

Bell and Gossett Distributors

As authorized Bell and Gossett distributors, we ensure prompt access to Bell and Gossett’s industry-leading solutions, which meet the various demands of clients across the areas of Austin, Houston, and San Antonio, Texas.